Electronic connectors play a critical role in modern technology, serving as the vital links between components in countless devices and systems. As industries push the boundaries of what’s possible, the demand for more resilient, efficient, and versatile connectors continues to grow. Designing durable electronic connectors requires a deep understanding of material science, electrical engineering, and environmental factors. This expertise is essential to create connectors that can withstand harsh conditions while maintaining optimal performance.

Environmental stress factors in electronic connector design

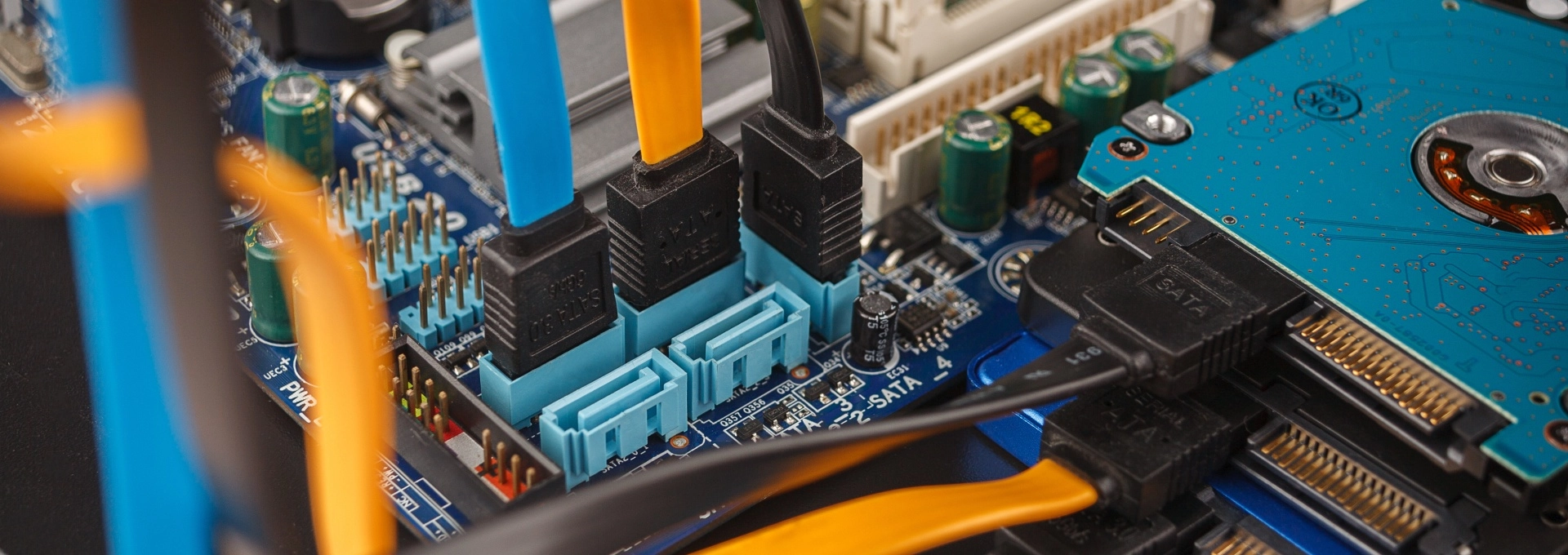

When designing electronic connectors, engineers must consider a myriad of environmental stressors that can impact performance and longevity. Temperature fluctuations, humidity, corrosive substances, and mechanical stress are just a few of the factors that can compromise connector integrity. These environmental challenges are particularly pronounced in industries such as automotive, aerospace, and marine applications, where connectors must maintain reliable connections under extreme conditions.

Temperature cycling, for instance, can cause materials to expand and contract, potentially leading to loose connections or physical damage to the connector structure. Humidity and moisture ingress can result in corrosion of metal contacts, while exposure to chemicals or oils may degrade insulating materials. Additionally, constant vibration or shock can cause fretting corrosion, a phenomenon where micro-movements lead to wear and oxidation of contact surfaces.

To address these challenges, designers must employ a holistic approach that considers not only the individual components of the connector but also how they interact under various environmental stresses. This often involves rigorous testing protocols that simulate real-world conditions, allowing engineers to identify potential failure points and optimize designs accordingly. The goal is to create connectors that maintain their electrical and mechanical properties across a wide range of environmental conditions, ensuring reliable performance throughout the connector’s intended lifespan.

Material selection for connector durability

The choice of materials is paramount in designing durable electronic connectors. Each component, from the housing to the contacts, must be carefully selected to withstand the specific environmental challenges of the intended application. The Connector guide provides valuable insights into various connector types and their features, which can inform material selection decisions. Let’s explore some key materials and their applications in connector design.

High-performance thermoplastics: PEEK and PPS applications

High-performance thermoplastics like Polyether Ether Ketone (PEEK) and Polyphenylene Sulfide (PPS) have become increasingly popular in connector design due to their exceptional properties. PEEK, known for its high temperature resistance and excellent mechanical strength, is often used in connectors for aerospace and automotive applications where extreme conditions are the norm. PPS, on the other hand, offers excellent chemical resistance and dimensional stability, making it ideal for connectors in harsh industrial environments.

Metal alloy choices: brass vs. beryllium copper

The selection of metal alloys for connector contacts and other conductive components is crucial for ensuring optimal electrical performance and durability. Two commonly used alloys in connector design are brass and beryllium copper, each with its own set of advantages.

Brass, an alloy of copper and zinc, is widely used due to its good conductivity, corrosion resistance, and cost-effectiveness. It’s particularly suitable for applications where moderate strength and conductivity are required. However, in more demanding environments, beryllium copper often takes the lead.

Corrosion-resistant plating: gold, silver, and nickel finishes

To enhance the durability and performance of electronic connectors, various plating materials are applied to the contact surfaces. The choice of plating can significantly impact a connector’s resistance to corrosion, wear, and environmental degradation. Gold, silver, and nickel are among the most common plating materials, each offering unique benefits.

Gold plating is renowned for its excellent corrosion resistance and low contact resistance. It’s particularly effective in low-voltage, low-current applications where signal integrity is critical. Gold-plated connectors are often found in high-reliability systems such as medical devices and aerospace equipment.

Silver plating offers high conductivity and good resistance to oxidation, making it suitable for power connectors and high-frequency applications. However, it’s more prone to sulfur-based tarnishing than gold, which can affect its long-term performance in certain environments.

Nickel plating provides a hard, wear-resistant surface that’s particularly effective in protecting against corrosion. It’s often used as an undercoat for gold plating to reduce costs while maintaining good performance. Nickel-plated connectors are common in automotive and industrial applications where durability is key.

The selection of plating material depends on factors such as the operating environment, electrical requirements, and cost considerations. Engineers must carefully balance these factors to choose the most appropriate plating for each specific connector application.

Elastomeric seals: silicone vs. fluorosilicone performance

Elastomeric seals play a crucial role in protecting electronic connectors from environmental ingress. Two materials commonly used for seals are silicone and fluorosilicone, each with its own set of characteristics suited to different applications.

Silicone seals offer excellent flexibility and resilience over a wide temperature range, typically from -55°C to 200°C. They maintain their properties well in dry environments and have good resistance to ozone and UV radiation. Silicone is often the go-to choice for general-purpose sealing in many connector designs.

Contact design optimization for reliability

The design of connector contacts is a critical aspect of ensuring reliable electrical connections. Optimizing contact design involves considering factors such as contact geometry, material properties, and the specific requirements of the application. Let’s explore some key aspects of contact design optimization.

Spring contact geometries: cantilever vs. bellows designs

Two common spring contact geometries used in electronic connectors are cantilever and bellows designs. Each offers distinct advantages and is suited to different applications.

Cantilever contacts consist of a flat beam that flexes when mated, providing the necessary contact force. They are relatively simple to manufacture and offer good reliability in many applications. Cantilever designs are particularly effective in connectors where space is limited and a low insertion force is desired.

Contact force analysis using finite element method (FEM)

Optimizing contact force is crucial for ensuring reliable electrical connections while minimizing wear and insertion force. Finite Element Method (FEM) analysis has become an indispensable tool for engineers designing connector contacts. FEM allows designers to simulate the mechanical behavior of contacts under various conditions, providing valuable insights into stress distribution, contact pressure, and deformation.

Wiping action mechanisms for contact cleaning

Wiping action in connector contacts is a crucial mechanism for maintaining clean contact surfaces and ensuring reliable connections over time. As connectors are mated and unmated, the sliding motion between contact surfaces helps to remove oxidation, debris, and other contaminants that can accumulate and impede electrical performance.

Effective wiping action depends on several factors:

- Contact geometry and surface finish

- Mating force and engagement distance

- Material properties of the contact surfaces

- Presence of lubricants or protective coatings

Designers must carefully consider these factors to optimize wiping action without causing excessive wear or increasing insertion forces beyond acceptable levels. For example, angled contact designs can enhance wiping action by increasing the sliding distance during mating, while textured surfaces can improve debris removal.

Fretting corrosion mitigation strategies

Fretting corrosion is a significant concern in connector design, particularly in applications subject to vibration or thermal cycling. This phenomenon occurs when micro-movements between mated contacts lead to wear and oxidation of the contact surfaces, potentially causing increased contact resistance and even electrical failure.

Ingress protection (IP) ratings for harsh environments

Ingress Protection (IP) ratings are crucial in specifying the environmental protection provided by electrical enclosures and connectors. These standardized ratings, defined by IEC 60529, indicate the degree of protection against solid objects, dust, and water. For connectors designed for harsh environments, achieving appropriate IP ratings is essential to ensure long-term reliability and performance.

The IP rating system uses two digits:

- The first digit (0-6) indicates protection against solid objects and dust

- The second digit (0-9) indicates protection against water ingress

For example, an IP67-rated connector is fully protected against dust (6) and can withstand temporary immersion in water up to 1 meter deep for 30 minutes (7). Connectors for outdoor or industrial applications often require high IP ratings to withstand challenging environmental conditions.

Achieving high IP ratings involves careful design considerations, including:

- Use of robust sealing materials and techniques

- Incorporation of protective housings or shells

- Design of effective mating interfaces

- Selection of materials resistant to environmental factors

Engineers must balance the need for ingress protection with other design factors such as ease of use, cost, and maintenance requirements. Rigorous testing is necessary to validate IP ratings and ensure connectors meet the specified protection levels in real-world conditions.

Electromagnetic interference (EMI) shielding techniques

As electronic systems become more complex and operate at higher frequencies, the need for effective Electromagnetic Interference (EMI) shielding in connectors becomes increasingly critical. EMI can cause signal degradation, data loss, and even system failures if not properly managed. Connector designers must employ various shielding techniques to ensure signal integrity and compliance with electromagnetic compatibility (EMC) standards.

Conductive elastomer gaskets: silver-filled silicone applications

Conductive elastomer gaskets, particularly those made from silver-filled silicone, are widely used for EMI shielding in connector designs. These gaskets provide an effective barrier against electromagnetic radiation while maintaining flexibility and conformability to irregular surfaces. Silver-filled silicone offers several advantages for EMI shielding applications:

- Excellent conductivity for effective EMI attenuation

- Good compression set resistance for long-term sealing

- Wide temperature range compatibility

- Resistance to environmental factors such as moisture and UV radiation

When incorporating conductive elastomer gaskets into connector designs, engineers must consider factors such as compression force, gasket dimensions, and surface finish of mating components to ensure optimal shielding performance.

Metallic shell designs: die-cast zinc vs. machined aluminum

Metallic shells play a crucial role in providing EMI shielding for connectors. Two common materials used for connector shells are die-cast zinc and machined aluminum, each offering distinct advantages.

Die-cast zinc shells are cost-effective for high-volume production and offer good EMI shielding properties. They can be easily molded into complex shapes and provide excellent dimensional stability. However, zinc is heavier than aluminum and may not be suitable for weight-sensitive applications.

Machined aluminum shells, while generally more expensive to produce, offer several benefits:

- Lighter weight compared to zinc

- Excellent thermal conductivity</

- Higher thermal conductivity

- Better corrosion resistance in certain environments

- Ability to be anodized for enhanced durability and aesthetics

The choice between die-cast zinc and machined aluminum depends on factors such as production volume, weight requirements, and environmental considerations. In some cases, hybrid designs incorporating both materials may be used to optimize performance and cost-effectiveness.

Ferrite beads and chokes for high-frequency noise suppression

Ferrite beads and chokes are essential components in EMI suppression for high-frequency applications. These passive devices work by absorbing and dissipating high-frequency electromagnetic energy, effectively reducing noise in electronic circuits. When incorporated into connector designs, ferrite components can significantly improve signal integrity and EMC performance.

Ferrite beads offer several advantages for connector EMI shielding:

- Broad frequency range effectiveness, typically from 1 MHz to 1 GHz

- Low DC resistance, minimizing impact on signal strength

- Compact size, allowing for integration into space-constrained designs

- Cost-effective solution for noise suppression

When designing connectors with ferrite components, engineers must consider factors such as the target frequency range, required attenuation levels, and the specific characteristics of the ferrite material. Proper placement of ferrite beads or chokes within the connector assembly is crucial for optimal performance.

Vibration and shock resistance in connector systems

Vibration and shock resistance are critical factors in connector design, especially for applications in automotive, aerospace, and industrial environments. Connectors must maintain reliable electrical connections even when subjected to severe mechanical stresses. Achieving robust vibration and shock resistance involves a combination of design strategies and material choices.

Key considerations for enhancing vibration and shock resistance include:

- Contact design optimization to maintain consistent contact force

- Use of flexible contact materials to absorb vibration

- Implementation of positive locking mechanisms to prevent accidental disconnection

- Selection of shock-absorbing materials for connector housings

- Incorporation of strain relief features to protect cable terminations

One effective approach to improving vibration resistance is the use of floating contact designs. These allow for slight movement of contacts within the connector housing, helping to maintain consistent contact pressure even under vibration. Additionally, spring-loaded contacts can provide a degree of compliance that helps absorb shock and vibration.